LnO Supply co.

We source, configure, and supply specialized equipment for commercial mushroom production — from lab to harvest.

Focused on practical, hard-to-find solutions for growers scaling reliable production.

LnO Supply

We source, configure, and supply specialized equipment for commercial mushroom production — from lab to harvest.

Focused on practical, hard-to-find solutions for growers scaling reliable production.

What We Do

Specialized sourcing for commercial mushroom production

LnO Supply helps mushroom growers find and configure equipment that actually fits their production needs.

We focus on:

Proven, commercial-grade equipment

European manufacturers and reliable suppliers

Real-world farm workflows, not theoretical setups

Honest guidance on what you need — and what you don’t

Cultivation & Fruiting

Stable environmental conditions are the foundation of consistent yields. We supply modular infrastructure for fruiting rooms and incubation spaces — designed for humidity, airflow, and long-term reliability.

Grow Tents

Controlled micro-environments for pilot projects and small-scale production.

Read more

Typical specifications

- Light-proof, washable interiors

- Integrated ventilation ports

- Multiple size options

- Suitable for incubation or fruiting

Sourcing & configuration

Selected commercial-grade models suitable for continuous operation.

Ultrasonic Humidifiers

Fine-mist humidification for precise environmental control.

Read more

Typical specifications

- High-output ultrasonic mist generation

- Low heat emission

- Compatible with automated controllers

- Scalable for single or multiple rooms

Sourcing & configuration

Configured based on room volume, airflow, and target humidity levels.

CO₂ Sensor & Humidity Controllers

Automated monitoring and control of critical growth parameters.

Read more

Typical specifications

- Real-time CO₂ and RH monitoring

- Programmable thresholds

- Integration with fans and humidifiers

- Industrial-grade sensors

Sourcing & configuration

System-level integration for stable and repeatable growth conditions.

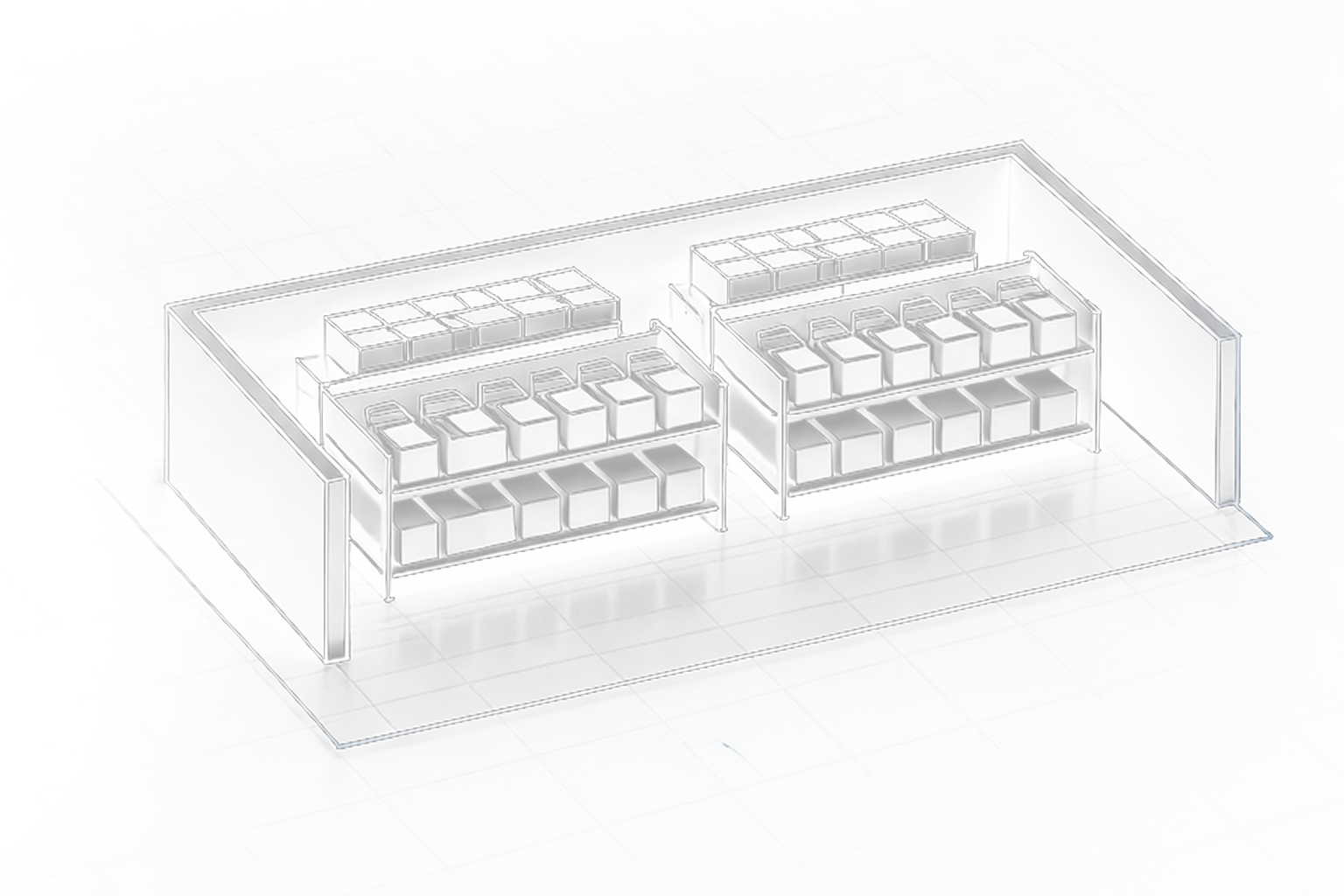

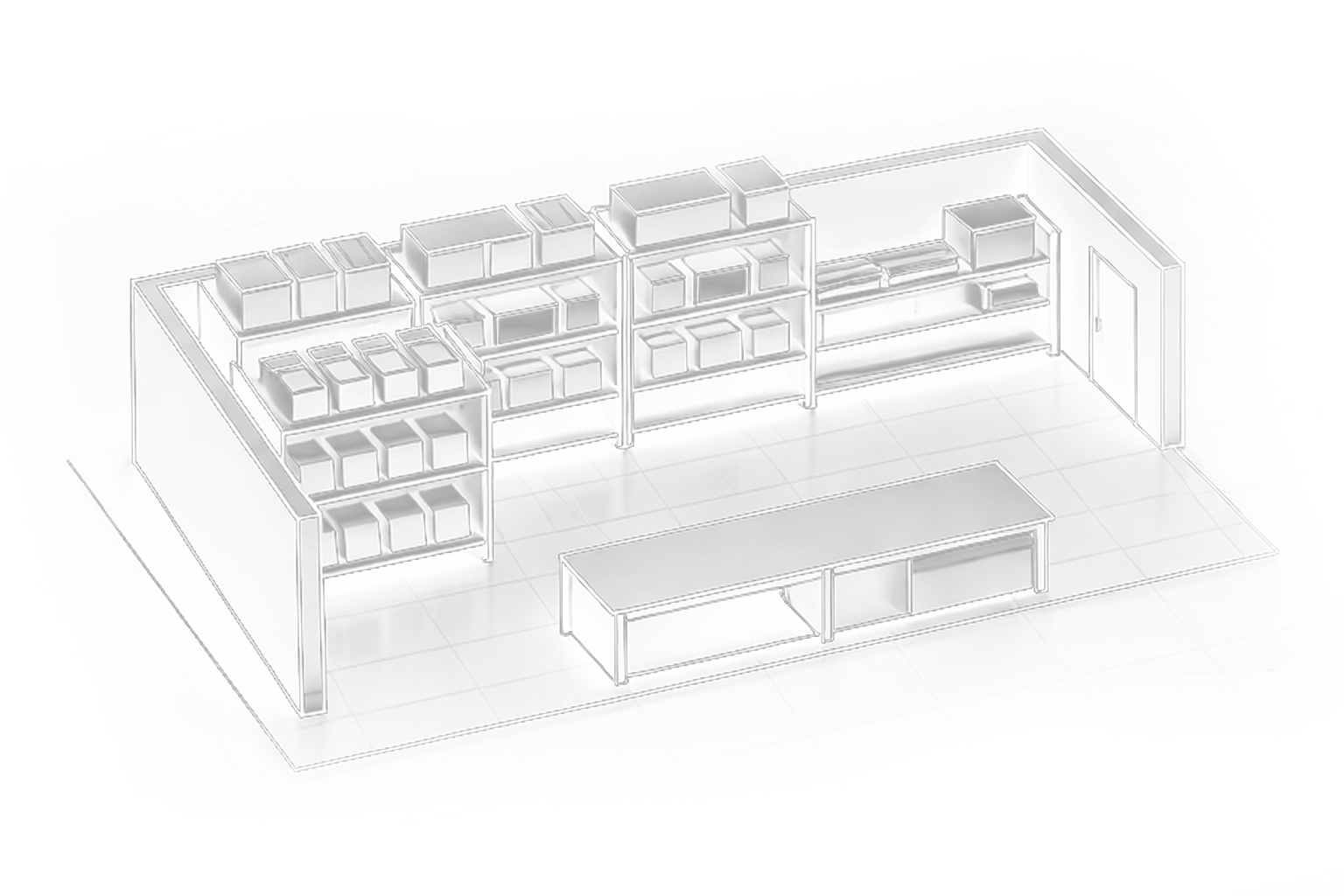

Stainless Commercial Shelving

Durable, food-safe shelving systems for fruiting rooms and incubation areas.

Read more

Typical specifications

- Food-grade stainless steel

- Modular, expandable designs

- High load capacity for bag or block cultivation

- Corrosion-resistant for high-humidity environments

Sourcing & configuration

Custom shelf layouts adapted to room dimensions and cultivation method.

Substrate & Processing

Efficient substrate handling saves time, labor, and frustration.

We source equipment that supports repeatable processing — from filling and mixing to conditioning.

Bag Filling Systems

Efficient and repeatable substrate bag filling.

Read more

Typical specifications

- Manual and semi-automatic options

- Compatible with various substrate mixes

- Adjustable fill volume

- Stainless steel contact surfaces

Sourcing & configuration

Matched to your substrate type and target throughput.

Bag Shakers

Even substrate distribution inside grow bags.

Read more

Typical specifications

- Reduces air pockets

- Improves colonization consistency

- Compact, operator-friendly design

Sourcing & configuration

Standalone units or integrated into filling lines.

Bag Breakers

Automated breakup of fully colonized substrate.

Read more

Typical specifications

- Reduces manual labor

- Consistent particle size

- Suitable for bulk or bagged substrates

Sourcing & configuration

Selected based on production scale and downstream process.

Substrate Barrels

Thermal and mixing containers for substrate preparation.

Read more

Typical specifications

- Food-safe materials

- Suitable for hot water or steam treatment

- Multiple volume options

Sourcing & configuration

Compatible with pasteurization and conditioning workflows.

Spawn & Lab Equipment

Clean workflows and controlled environments are critical for healthy cultures. We provide lab-grade equipment suitable for daily production use, not just hobby setups.

Laminar Flow Hoods & HEPA Filtration

Clean air solutions for sterile lab work.

Read more

Typical specifications

- HEPA-filtered laminar airflow

- Bench-top or freestanding units

- Suitable for inoculation and culture work

Sourcing & configuration

Sized for lab layout and workflow.

UV Equipment Sanitizers

Rapid surface and tool sanitation.

Read more

Typical specifications

- UV-C sterilization

- Compact footprint

- Suitable for tools and containers

Sourcing & configuration

Supplementary sanitation for clean lab environments.

Bag Sealers

Reliable sealing of grow bags after filling.

Read more

Typical specifications

- Adjustable sealing width

- Consistent heat control

- Designed for continuous operation

Sourcing & configuration

Matched to bag thickness and production speed.

Stainless Steel Work Tables

Durable work surfaces for lab and processing areas.

Read more

Typical specifications

- Food-grade stainless steel

- Easy to clean

- Custom dimensions available

Sourcing & configuration

Designed to fit your room layout and workflow.

Harvest, Handling & Storage

Post-harvest handling directly impacts quality and shelf life.

We help growers design cold storage and handling solutions that fit their harvest volumes and logistics.

Food-Grade Harvest Crates & Lids

Reusable containers for clean harvest handling.

Read more

Typical specifications

- Food-safe plastics

- Stackable and collapsible options

- Optional lids

Sourcing & configuration

Optimized for transport, washing, and storage efficiency.

Refrigerators & Additional Shelving

Cold storage for fresh harvests.

Read more

Typical specifications

- Commercial-grade units

- Adjustable shelving

- Energy-efficient operation

Sourcing & configuration

Matched to harvest volume and available space.

Compact Cold Room Units

Modular walk-in cold storage solutions.

Read more

Typical specifications

- Scalable room sizes

- Temperature-controlled systems

- Suitable for fresh mushrooms

Sourcing & configuration

Designed for indoor installation with minimal footprint.

Mini-Split to Refrigerator Converters

Cost-efficient cooling for cold rooms.

Read more

Typical specifications

- Converts standard mini-split AC units

- Precise temperature control

- Energy-efficient alternative to traditional systems

Sourcing & configuration

Integrated into custom cold room setups.

How sourcing with LnO Supply works

Step 1 – Understand your setup

We start by understanding your production scale, space, and workflow.

Step 2 – Define the right equipment

Based on your needs, we identify suitable equipment options — including alternatives and trade-offs.

Step 3 – Source & configure

We source from trusted suppliers and help configure systems to work together.

Step 4 – Ongoing support

As your production evolves, we help you adapt and expand your setup.

Who We Work With

LnO Supply works with:

Commercial mushroom farms

Growers scaling from pilot to production

Food producers integrating mushrooms into existing operations

Projects requiring custom or hard-to-source equipment

If you are looking for:

Off-the-shelf hobby kits

Drop-shipped consumer products

We’re probably not the right fit — and that’s okay.

Request a Quote

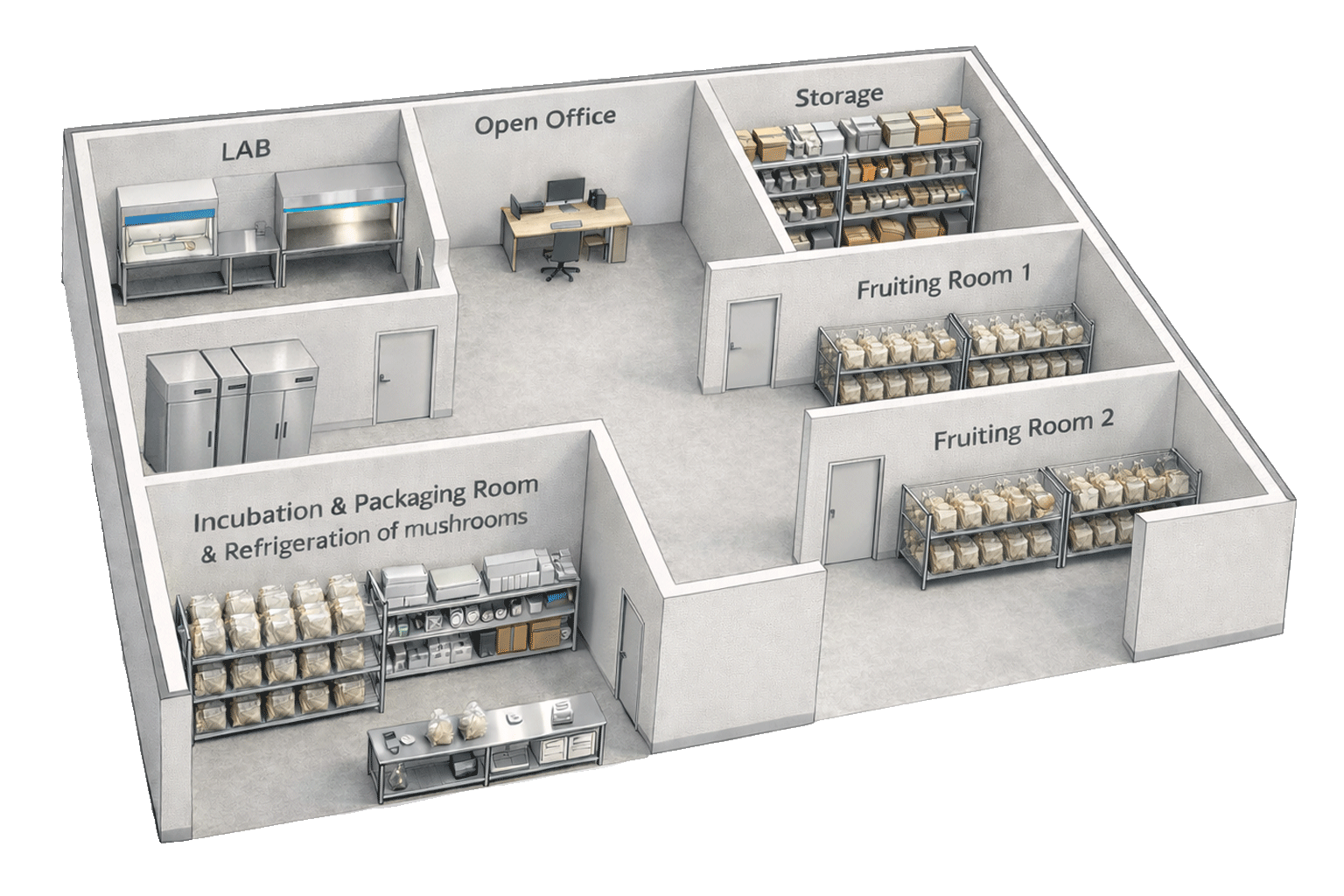

Mushroom Farm Consulting

In addition to equipment sourcing, LnO Supply offers consulting for mushroom farm design and optimization.

This includes:

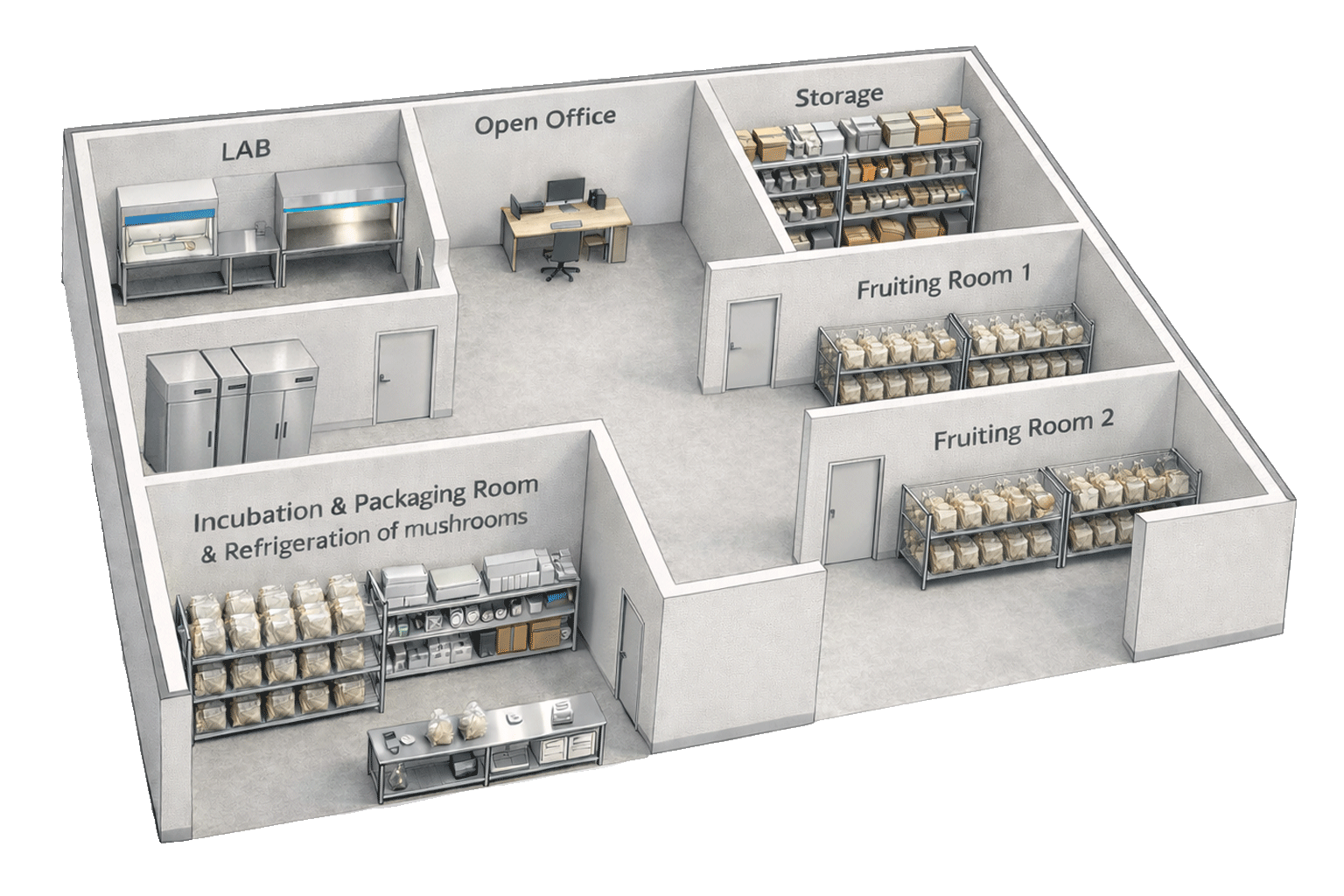

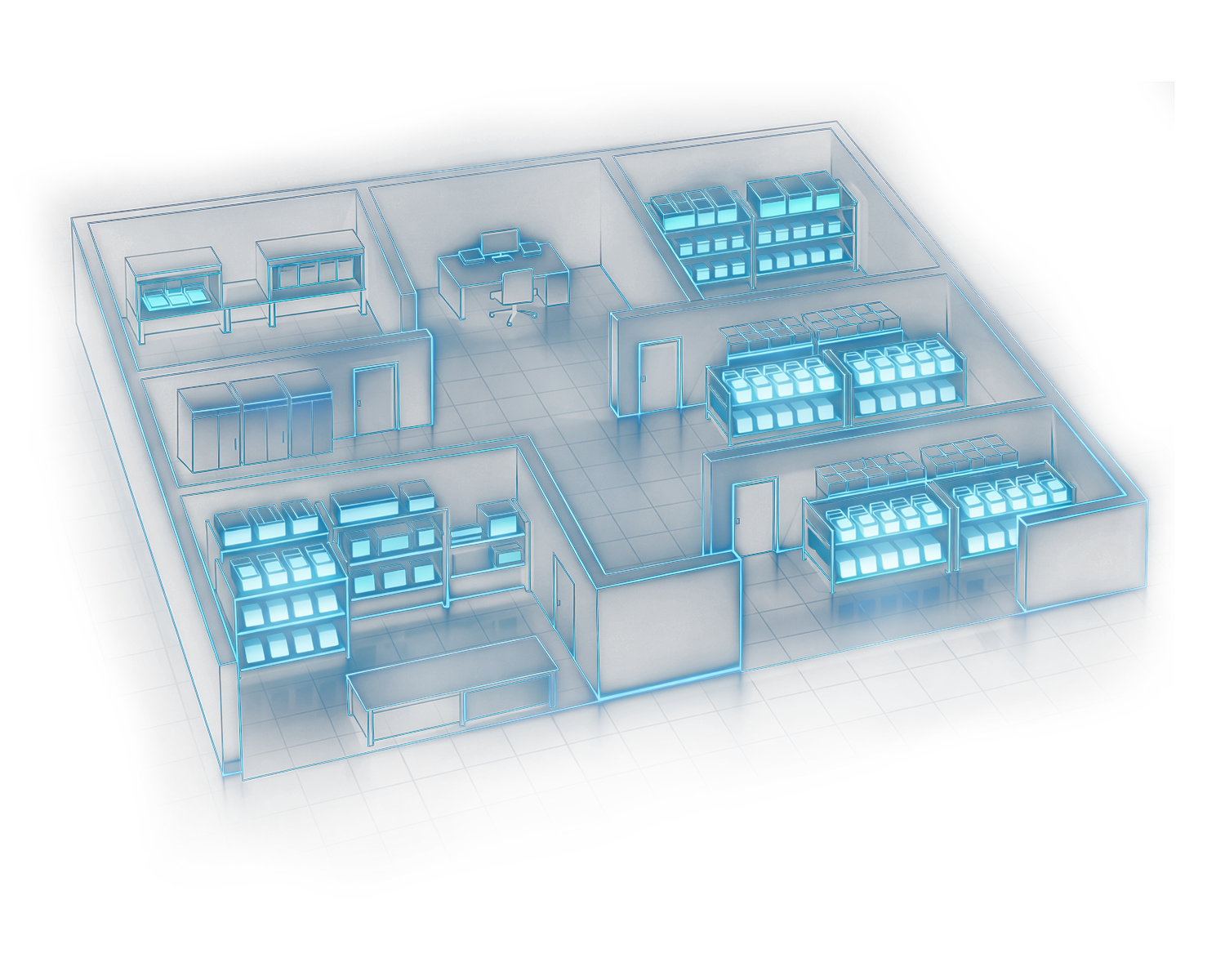

Production layout planning

Workflow optimization

Equipment integration

Scaling strategies

Consulting is always practical, production-focused, and grounded in real farm experience.